The project intends to develop and demonstrate software algorithms that will allow selective laser melting (SLM) to produce metal parts that are high quality and durable. Currently, there is no common approach to SLM that comprehensively reduces problems associated with this method such as surface roughness, residual stress, porosity and micro-cracking. Without careful optimization of the process, these issues may cause parts to fail.

‘With the SLM processes in place now, you don’t always end up with a part that is structurally sound,’ said Ibo Matthews, a researcher with LLNL’s Accelerated Certification of Additively Manufactured Metals Strategic Initiative team who is leading the Lab’s effort on the joint project. ‘It’s critical to have mechanically robust parts, especially for applications in industries such as aerospace and energy, where part failure could lead to major problems.’

Error issues

In order to print a 3D part using the SLM process, the user must enter data into the printer using a stereolithography (STL) file, which is a digitized 3D representation of the desired build.

‘Ideally, you would send the STL file to an arbitrary 3D printer and it will print out parts that are consistent in terms of dimensions and material properties,’ said Matthews. ‘Currently, that doesn’t happen.’

This is because errors appear during the initial translation of the STL file, requiring the user to fill in missing information as well as specify the type of powder material used. To further complicate matters, traditional printer designs treat every layer of powder the same, without giving consideration to the thermal properties of the powder. Some printer systems provide more control than others.

In an ideal system, different layers would demand different laser scanning speeds and powers because the powder environment is changing as the layer-by-layer buildup proceeds.

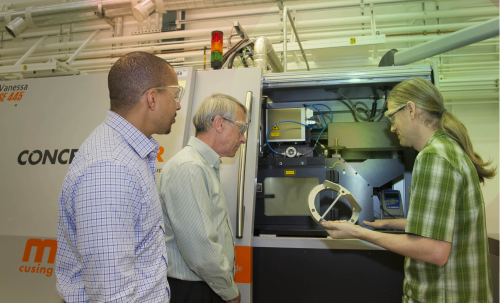

‘Commercial SLM machines do not permit access to specific process parameter information and tool paths,’ said Bill Carter, a researcher with GE’s Additive Manufacturing Lab, which is under GE’s Global Research. ‘This limits the ability of researchers to perform controlled validation experiments that support modeling work and process development. The cooperation of GE and LLNL will result in a demonstration of the new protocol on several research machines, paving the way for more robust process control and optimization strategies.’

‘If you were able to process a 3D part by telling the machine what are the right laser parameters for optimizing the heating and melting for each layer, then the overall manufacturing process can be made more robust and efficient,’ added Matthews.

Software algorithms

The engineers are developing software algorithms that will be compatible with all 3D printers that produce metal parts. This software will be able to control the scan laser’s parameters, such as beam size, scan rate and power, on the materials, its powder characteristics and the detailed shape of the part being printed.

Because the software will be available to the public, Matthews hopes it will lead to more breakthroughs in the AM industry.