The ultra-short pulsed laser deposition (USPLD) surface coating technology can create either porous or dense coatings on heat-sensitive substrates for use in a range of industrial metallisation applications.

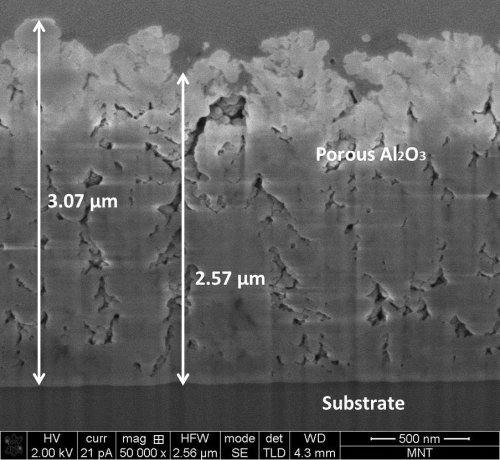

Porous Al2O3 layers can be used for instance as filters and electrical insulation layers. Dense Al2O3 is used as a barrier layer and is also an optical coating with high transmittance properties.

The Picodeon process enables micro-structural control of Al2O3 coatings by managing the coating process parameters on the comapny’s Coldab batch process coating equipment.

“This development has enormous potential for new applications of dense and porous aluminium oxide coatings on heat sensitive materials,” claimed Marko Mylläri, Picodeon VP sales and business development. “It is currently very difficult to achieve these results using physical vapour deposition (PVD), sputtering or chemical vapour deposition (CVD) surface coating technologies.”

The Coldab equipment has built-in online plasma monitoring and laser power measurement that enable management of coating process parameters, and a PC controlled automation that records the actions of the coating process.

The metrics provided by these systems mean that the coating process, and especially the thin film quality, can be controlled with great accuracy to achieve coating characteristics within highly targeted parameters.