By Kari Williamson

Energy loss has long been a concern among vacuum furnace engineers and solutions have been slow in coming to market.

Solar Atmospheres' innovation is based on thermal loss calculations paired with extensive laboratory vacuum furnace testing.

The improved hot zone is said to be more energy-efficient in the same insulation dimensions and without compromising vacuum performance. Although initial costs are somewhat higher, payback with reduced energy costs is expected within the first year of operation with significant savings to occur in the following years.

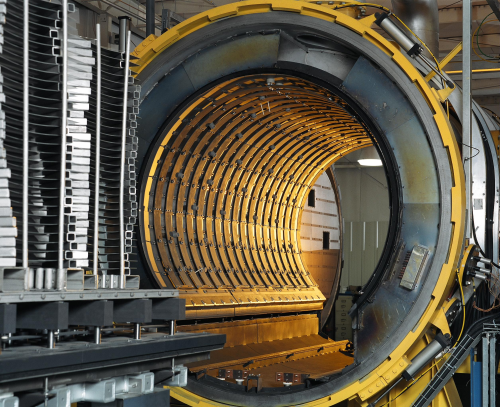

To test-drive the design and make a direct comparison to current hot zones, Solar Atmospheres is rebuilding a mid-size production vacuum furnace hot zone in its corporate headquarters, Souderton, Pennsylvania, USA.

Very careful power measurements will be obtained with a Fluke Model 1735, true RMS, power computer and with fixed hot zone thermocouples placed within the new hot zone insulation system at soaking temperatures of 1600°F, 1800°F, 2000°F, 2200°F, 2400°F, 2600°F and 2800°F to prove out the design.