Following a competition win, the Fraunhofer Institute for Laser Technology ILT has been contracted by ASTM International to help standardize machine condition monitoring in laser beam powder bed fusion (LB-PBF).

The institute will reportedly focus on selecting and qualifying imaging sensor technology used to monitor the condition of LB-PBF systems. It also plans to receive cost-reducing recommendations for end users from these data.

The contract is part of a new funding mechanism, called Call for Projects (CFP), set up by ASTM which allows organizations globally to submit proposals for addressing AM standardization gaps and receive support from ASTM.

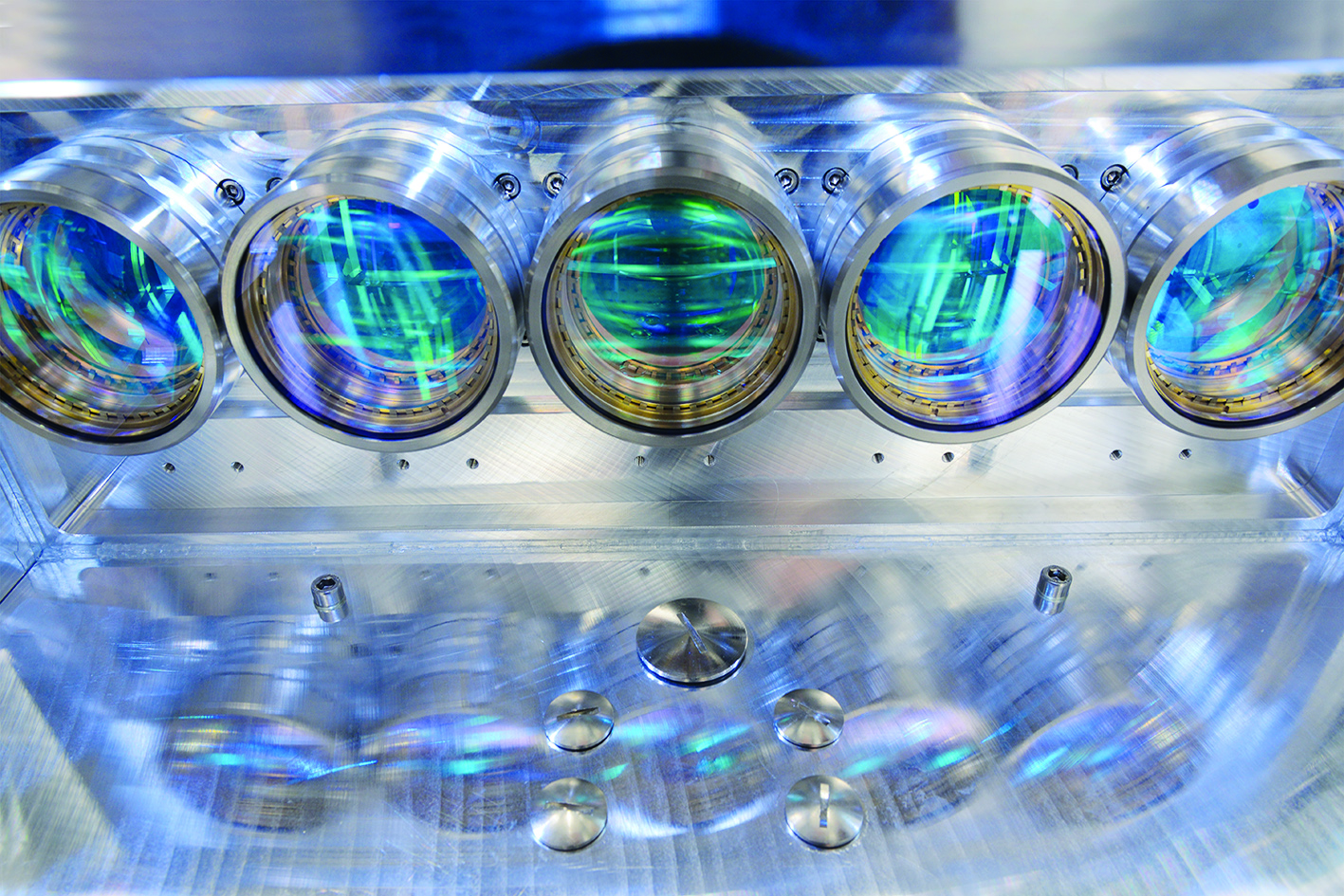

According to Fraunhofer, monitoring LB-PBF systems in particular is important because very fine metal powder is used and optical systems can become contaminated during processing.

‘The load, probability of failure and maintenance effort of optical systems are increasing, while users still have to cope with maintenance guidelines based on little experience with previous system generations,’ said Niklas Prätzsch, project manager of LBF at Fraunhofer. ‘Manufacturers' current maintenance guidelines are often still far too conservative. In contrast to long-established manufacturing technologies, there is no or only a comparatively small database available as a basis for making decisions whenever maintenance cycles need to be determined.

Fraunhofer ILT is now focusing on qualifying imaging sensor technology for monitoring highly loaded optical systems of LB-PBF machines and finding ways to help end users assess the condition of optical systems and plan maintenance cycles by using real data rather than subjective perception.

This story uses material from Fraunhofer, with editorial changes made by Materials Today.