3D printing company ExOne and Global Tungsten & Powders (GTP), which makes tungsten metal powders, have entered into a collaboration to develop tungsten-based metal 3D printing using binder jetting.

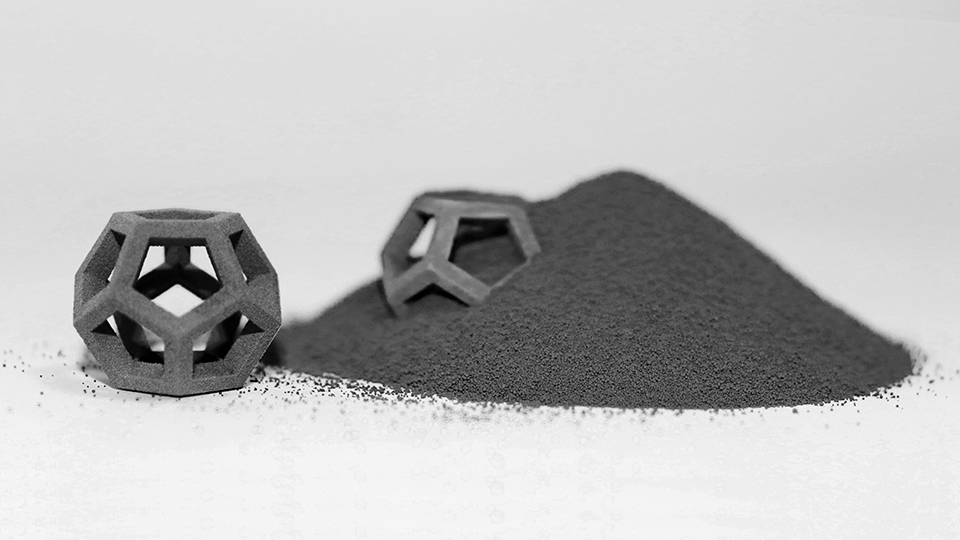

According to ExOne, binder jetting is a 3D printing process that uses a digital file to inkjet a bonding agent into a bed of powder particles, creating a solid part one layer at a time.

ExOne and GTP plan to develop two metal matrix composites: cemented carbide (WC-Co), a material with high hardness and toughness that is used for the production of cutting tools and wear-resistant parts, and copper-tungsten (CuW), which reportedly has high heat resistance, high electrical and thermal conductivity, and low thermal expansion.

‘Traditionally, tungsten carbide powder is pressed into the desired shape and then sintered to give it strength and density,’ said Deborah West, vice-president at GTP. ‘Instead of costly and timely mold construction, the parts now can be printed directly in the desired shape, still using sintering technology to achieve the final strength.’

GTP says that it will now offer a 3D printing and sintering service for cemented carbide parts, for end users wanting to test new designs. The company has installed an ExOne Innovent, a binder jetting system that 3D prints metal, ceramic and composite powders.

This story uses material from ExOne, with editorial changes made by Materials Today. The views expressed in this article do not necessarily represent those of Elsevier.