Additive manufacturing (AM) specialist the FIT Group has opened its German headquarters and new manufacturing facility – the first such facility worldwide to be totally conceived for AM, the company says.

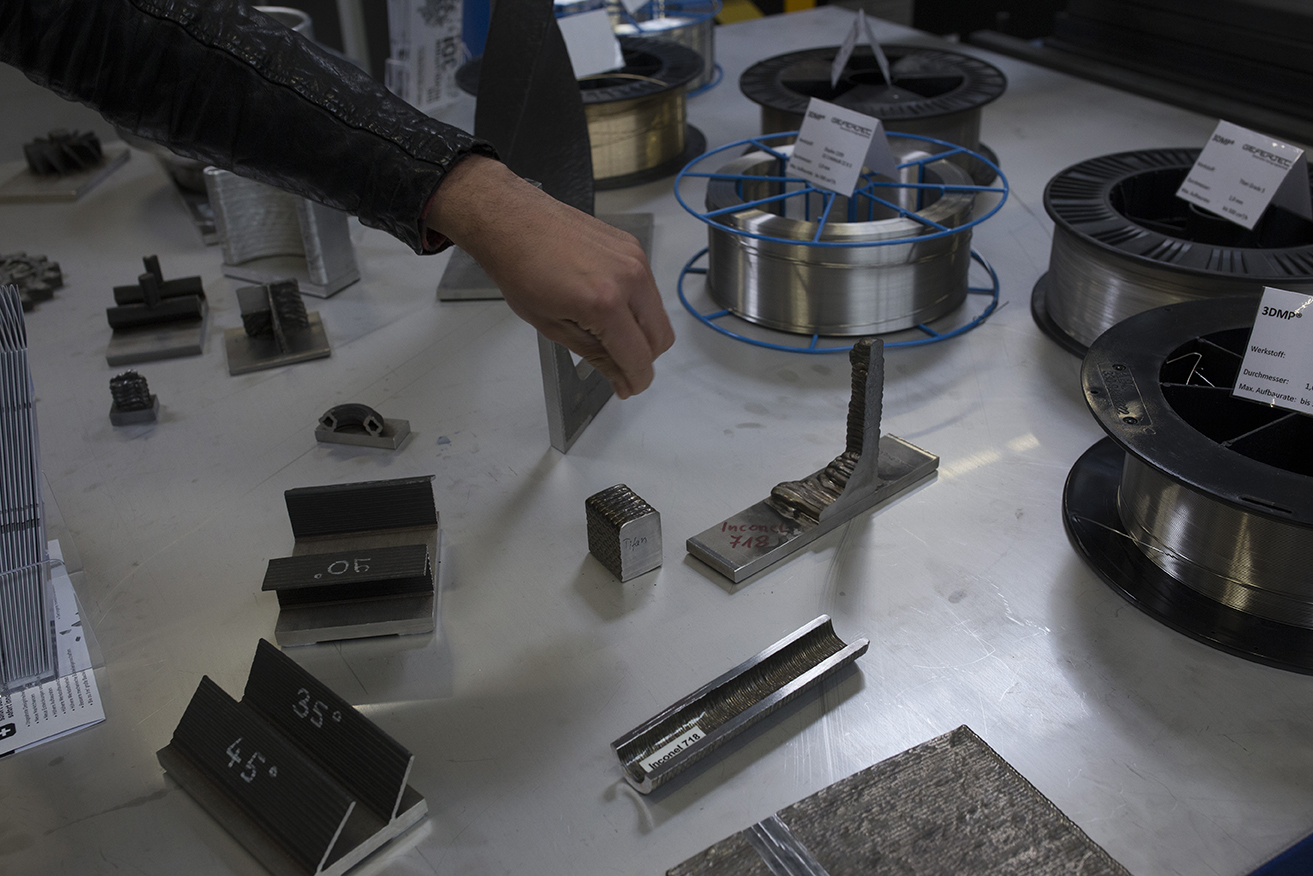

In 2014, FIT announced its plan to establish a facility solely for AM, with an investment of €20 million Euros. The whole ground floor of the factory is dedicated to 3D printing metal parts with, FIT says, the highest capacity for the AM of metal parts in the world.

The complete first floor (second floor for our US colleagues) is dedicated to the additive manufacturing of plastic parts. One of the major applications here is the manufacturing of prototypes for the automotive sector.

‘We firmly believe that AM should be a mainstream tool in industrial manufacturing,’ said Carl Fruth, founder and CEO of FIT AG. ‘Our goal is to create a digitized scalable factory and to develop standards for higher volume series metal AM. To get there, processes still have to be more stable, automated and cost-effective. That’s where we are putting all our energy and ambition every day.’

This story is reprinted from material from the FIT Group, with editorial changes made by Materials Today. The views expressed in this article do not necessarily represent those of Elsevier.