The University of Akron in Ohio, USA, and repair company Airborne Maintenance and Engineering Services plan to seek Federal Aviation Administration (FAA) approval for ‘cold spray’ repair of corroded and worn parts on commercial aircraft.

The public-private partnership initiative could receive the first FAA certification for full-scale commercial aircraft repair operations.

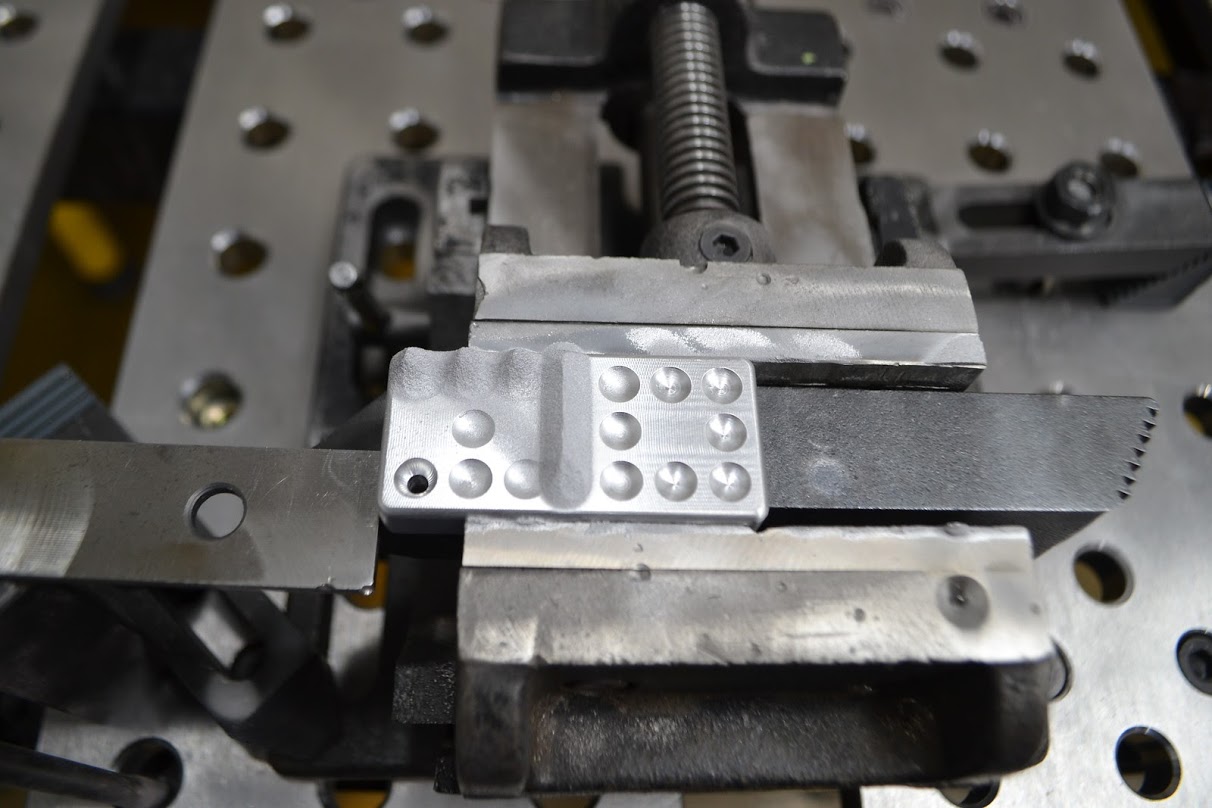

The technique involves a high pressure spraying process in which metal particles contained in a supersonic jet of an expanded gas impact a solid surface with sufficient energy to cause bonding with the surface. This additive manufacturing (AM) process, otherwise known as supersonic particle deposition (SPD), builds up and repairs the surface of the metal part without creating a heat-affected zone that would occur during welding or high temperature thermal spray.

Development and testing has been underway for two years and data gathered has provided the foundation with the information required for FAA approval of SPD dimensional restoration of aircraft structure, according to the organizations.

This story uses material from the University of Akron,with editorial changes made by Materials Today. The views expressed in this article do not necessarily represent those of Elsevier.