Early returns from FABTECH 2012, which took place at the Las Vegas Convention Center Nov. 12–14, suggest the show was highly successful event on several levels.

Show organizers kicked off a well-rounded, heavily attended event that lived up to the hype. Exhibitors enjoyed robust traffic, particularly on the first two days, with some reporting purchasing activity. Lastly, and more importantly, attendees representing various sectors of the North American manufacturing community got the opportunity network with both peers and vendor partners while reviewing the latest innovations in equipment, automated systems, and surface forming/finishing technology—all under one great, big roof.

According to show organizers,1 FABTECH 2012 drew 25,903 attendees—an 18% increase compared to the last time the show was held in Las Vegas.2 The sheer volume, observers say, is indicative of not only the vitality of the U.S. manufacturing sector, but also the willingness of job shops and captive operations to invest in capital equipment and training.

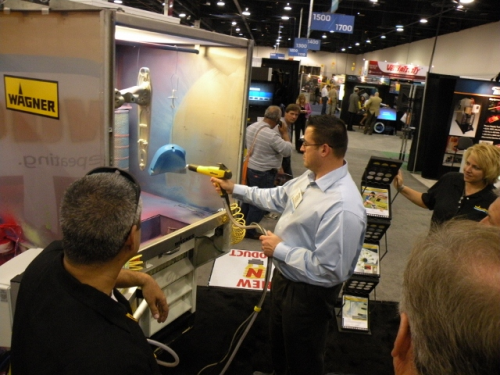

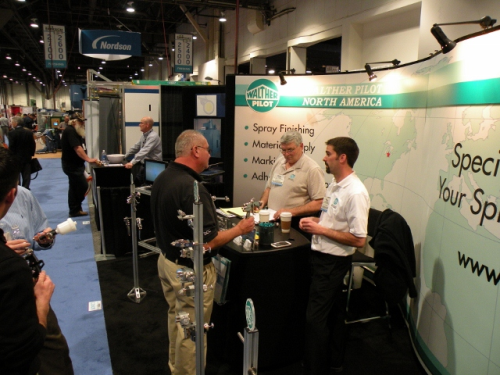

FINISHING PAVILION

The brisk activity was especially palpable in the Finishing Pavilion, which made its debut at FABTECH 2010 in Atlanta. According to Anne Goyer, executive director of the Chemical Coaters Association International, or CCAI, a FABTECH co-sponsor, this year’s Finishing Pavilion occupied its largest show floor space in the three years that it has been a part of the show. (More than 25,000 net square feet, to be more precise.)

“By all accounts, this was the best Finishing Pavilion & Conference at FABTECH yet,” Goyer told Metal Finishing. She said CCAI was pleasantly surprised that its show floor square footage surpassed that of FABTECH 2011, which was held at the sprawling McCormick Conference and Convention Center in Chicago. In fact, Goyer said CCAI had to expand its exhibit space three times to accommodate the requests for booth space in Las Vegas.

Likewise, Goyer said CCAI also saw a big jump in this year’s Finishing Conference sessions. By her count, CCAI more than doubled its sessions sold to 384 this year compared to 187 in Atlanta. Conference participation was up by more than 30% over the Chicago event (291).

“As we were tearing down, I had the chance to talk to quite a few conference attendees who told me the conference sessions they attended provided great information,” said Goyer, citing conference evaluations reflecting very high marks.

SOLID ALL AROUND

Finishing Pavilion exhibitors, not to be outdone, providing some generous scoring of their own. Cases in point: Kathy Wilson, marketing manager for AkzoNobel, was extremely pleased by the number of legitimate leads generated at her booth, while Mark Schmidt Jr., technical support specialist, Finishing Brands—representing DeVILBISS, Ransburg, BGK, and BINKS—said the traffic through his booth was rock steady. Similarly, Paul Lomax, Fischer Technology, had his hands full with a stream of curious attendees interested in demonstrations of thickness testing equipment.

And let’s not forget about the consuming public—those attendees comprising shop owners and managers who made the trip in search of innovative tools and new equipment to boost efficiency/profitability in their operations. That description fits those like Tony Sclafani, general manager of ARI Iron, LLC and AR Powder Coating, who primarily came to touch base with both existing and potential suppliers. In recent years, Sclafani expanded into the finishing business and wanted to meet with his cleaning and pretreatment vendor partners, as well as suppliers of turnkey finishing systems.

“We’re very loyal,” Sclafani told Metal Finishing. “When we find a good supplier, we tend to stick with them.”

For more in this story, look out for the November/December edition of Metal Finishing magazine. REFERENCES

- FABTECH 2012 is jointly sponsored by the American Welding Society, Fabricators & Manufacturers Association International, Society of Manufacturing Engineers, Precision Metalforming Association, and the Chemical Coaters Association International.

- Attendance as measured by the number of people who actually picked up a badge on site.