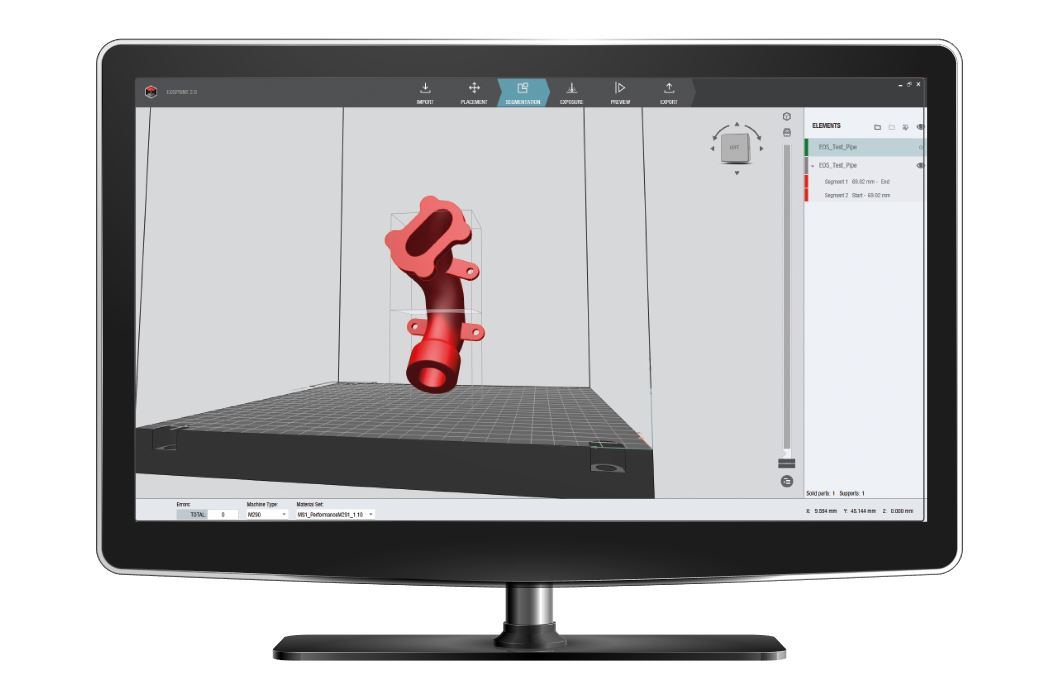

EOS has released a new version of its additive manufacturing (AM) CAM environment, EOSPRINT 2.0. The new EOS software can reportedly provide an intuitive user interface and offer customers greater freedom for application-specific parameter optimization and allow easier part optimization. EOSPRINT 2.0 is now available for EOS M 290 and EOS M 400 3D printers, while future iterations will include support for all current EOS metal systems and future polymer systems.

EOS says that EOSPRINT 2.0 introduces a workflow-based approach for the graphical user interface, reflecting the AM CAM process. This means that the software architecture is built around the workflow of data preparation for industrial 3D printing. New plane segmentation capabilities enable different layer thicknesses in one part, improving it more easily for production. The segmentation functionality enables the splitting of a part along a plane so that it can be shifted in z-level to define part segments with different exposure requirements regarding quality and productivity. As a result, engineers can define segments where a very high quality is needed and can assign machine parameters optimized for highest quality. Segments where speed is more important can be processed with parameters optimized for highest productivity.

This story is reprinted from material from EOS, with editorial changes made by Materials Today. The views expressed in this article do not necessarily represent those of Elsevier.