GKN says that its new coaxial electric axle system entitled the ‘eTwinsterX’ is now in the prototype stage, with a working example up-and-running in a demonstrator vehicle.

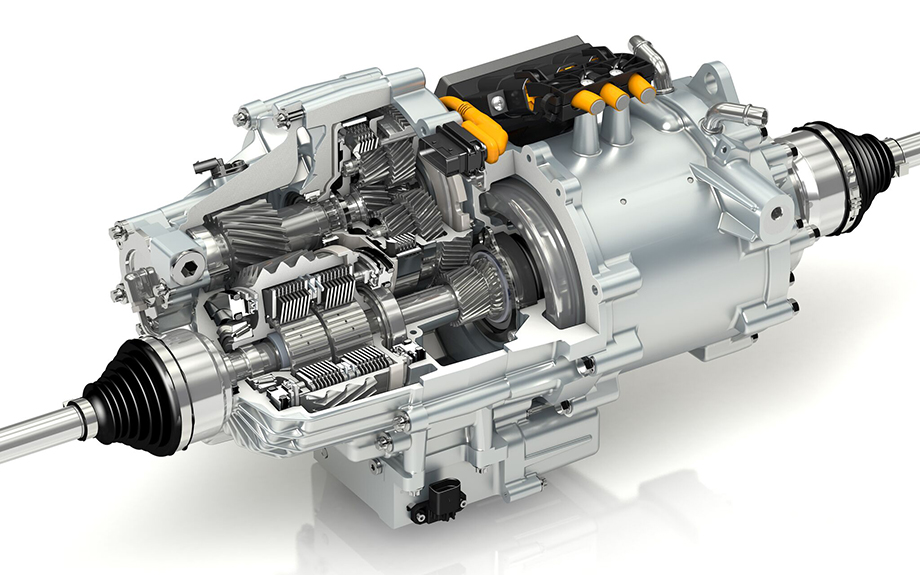

The eTwinsterX system features an integrated e-motor, two-speed e-transmission, and torque vectoring capability using GKN’s ‘Twinster’ clutch pack technology.

The eDrive system employs a 120kW downsized e-motor, delivers maximum torque of 3,500Nm, vectors up to 2,000Nm to each rear wheel, and can operate up to maximum vehicle speeds of around 250kph.

‘The dynamic development of eTwinsterX is testament to GKN’s unique position in being able to deliver an integrated e-motor, two-speed e-transmission and torque vectoring within a complete eAxle system,’ said Peter Moelgg, CEO of GKN Driveline’s AWD and eDrive business. ‘Our calibration expertise also means that we can optimise these technologies to deliver fully brand-aligned experiences for our global OEM customers.’

This story is reprinted from material from GKN, with editorial changes made by Materials Today. The views expressed in this article do not necessarily represent those of Elsevier.