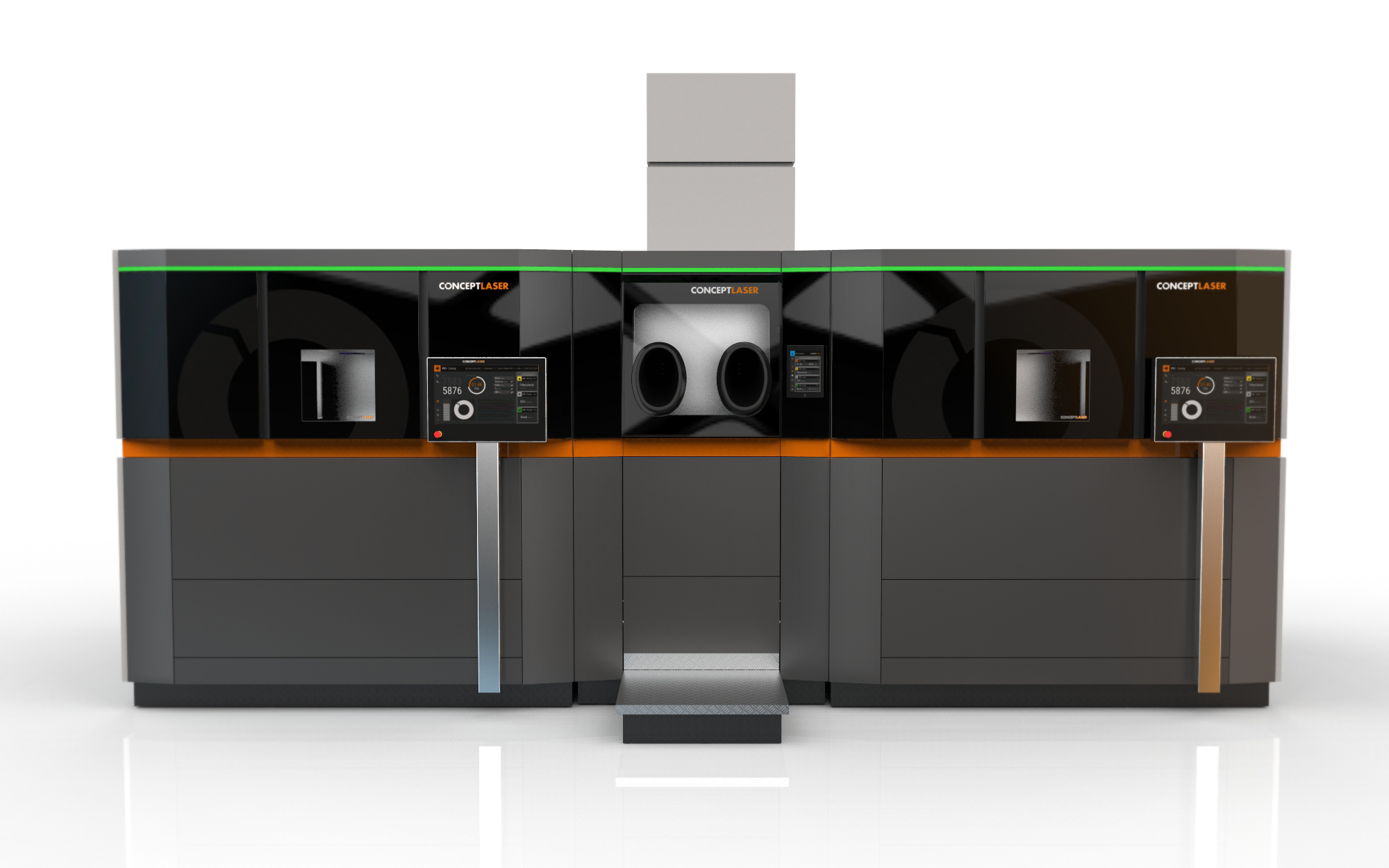

Concept Laser has developed what it calls a ‘smart factory’, a modular approach to additive manufacturing (AM) which makes it easier for production to be automated, digitized and interlinked. ‘The move away from ‘stand-alone’ solutions is making AM faster, more cost-effective and more industrial,’ the company said.

The company’s new stand-alone process stations have a build envelope of 400 x 400 x >400 mm³ equipped with 1 to 4 laser systems using multilaser technology with variable focus diameters including 400 W to 1,000 W laser sources. Also integrated in the machines is a 3D scanning system which helps enable real-time adjustment of the laser spot with diameters of from 50 – 500 μm.

The new machine concept also has a 2-axis coating system, which allows the coater to return in parallel with the exposure.

While the material storage facility, the process unit and the unit for collecting the excess material were previously connected together in a fixed manner, the new approach now envisages dividing these three sections into individual modules. These modules are independent of one another and can be controlled individually.

The company has also designed a new software architecture for controlling and monitoring machine components and the flow of data combining MDL (machine data logging) with ODL (operating data logging).

This story uses material from Concept Laser, with editorial changes made by Materials Today. The views expressed in this article do not necessarily represent those of Elsevier.