3D printing company Sintavia and Siemens Digital Industries Software have joined forces to develop end-to-end additive manufacturing (AM) software.

Sintavia says that will provide testing and technical feedback on Siemens’ Xcelerator software and will become its preferred AM partner. As part of the three-year agreement, the two companies will also collaborate on sales and marketing activities and plan to organize events at Sintavia’s facility featuring Siemens’ AM software.

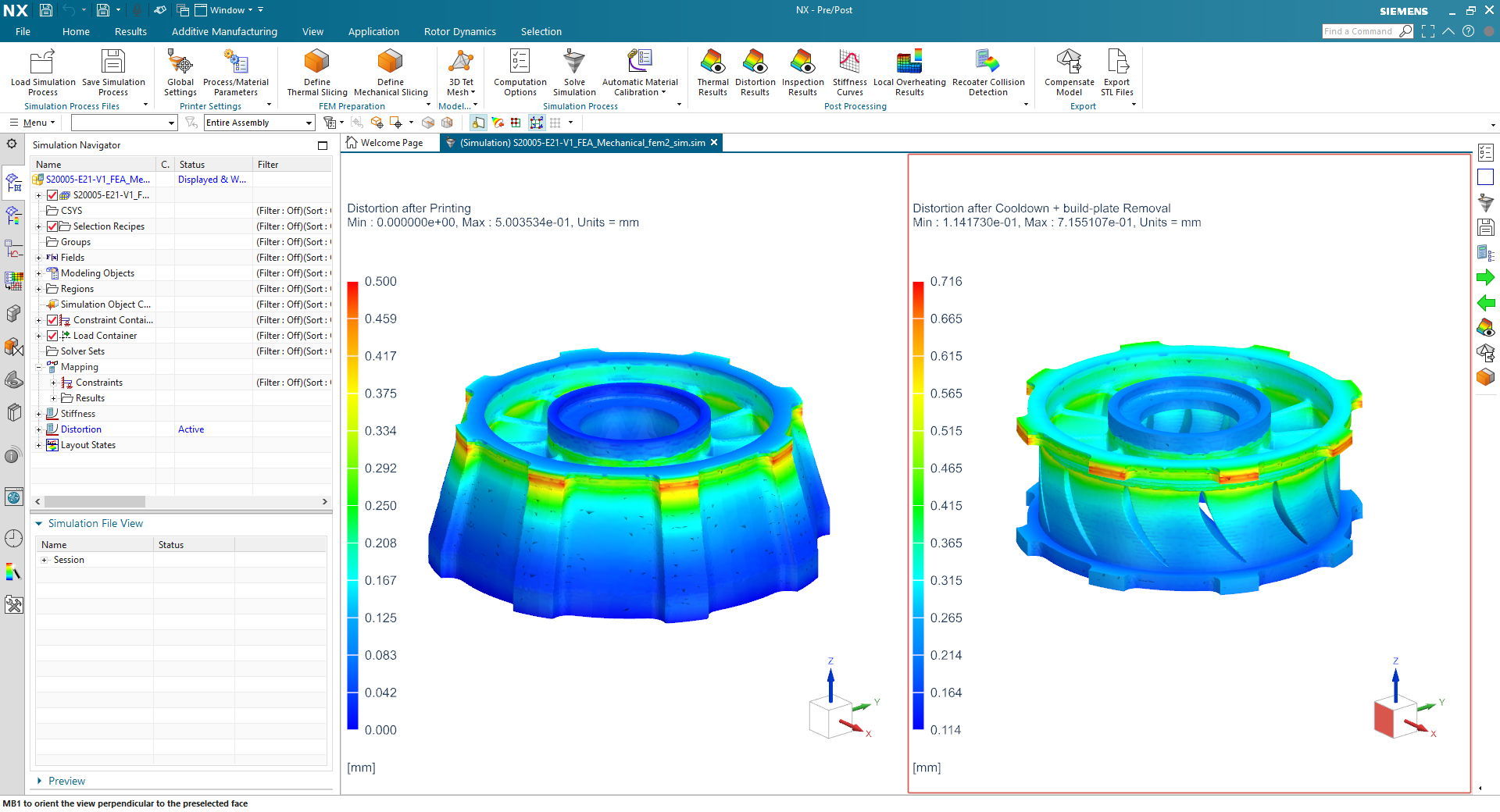

‘We’ve developed a lot of tribal knowledge on how to deliver quality 3D printed metal parts,’ said Brian Neff, CEO at Sintavia. ‘But we recognize that we can’t just rely on individual expertise to meet the accelerating demand in aerospace for additive manufacturing. We need software to codify the processes we undertake, and not just connect them in a digital thread, but automate them, take our know-how and have it drive activities in the background, so we can achieve optimal efficiency.’

The companies say that sustainability will be a focus area for their marketing collaboration.

This story uses material from Sintavia, with editorial changes made by Materials Today. The views expressed in this article do not necessarily represent those of Elsevier.