Additive manufacturing (AM) or 3D printing can create complex structures rapidly layer-by-layer that are unfeasible through conventional machining techniques. When partnered with computed aided design, AM enables quick prototyping of new products and the production of novel lightweight structures. It is particularly attractive for metal production because using high-powered lasers to rapidly melt and fuse together metal powders layer-by-layer creates highly intricate structures.

But getting an insight into exactly what is happening during the laser melting and fusing of metal powders has proven tricky. Now, however, researchers from Lawrence Livermore National Laboratory (LLNL) and Washington State University believe they can help [Martin et al., Materials Today Advances 1 (2019) 100002].

“There are significant gaps in our knowledge of how these processes couple together during laser heating and in particular at the high temperatures (2000-3000 K) used during laser-based AM of metals,” explains first author Aiden A. Martin of LLNL.

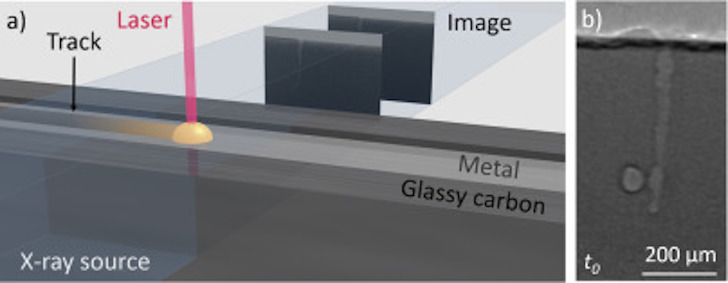

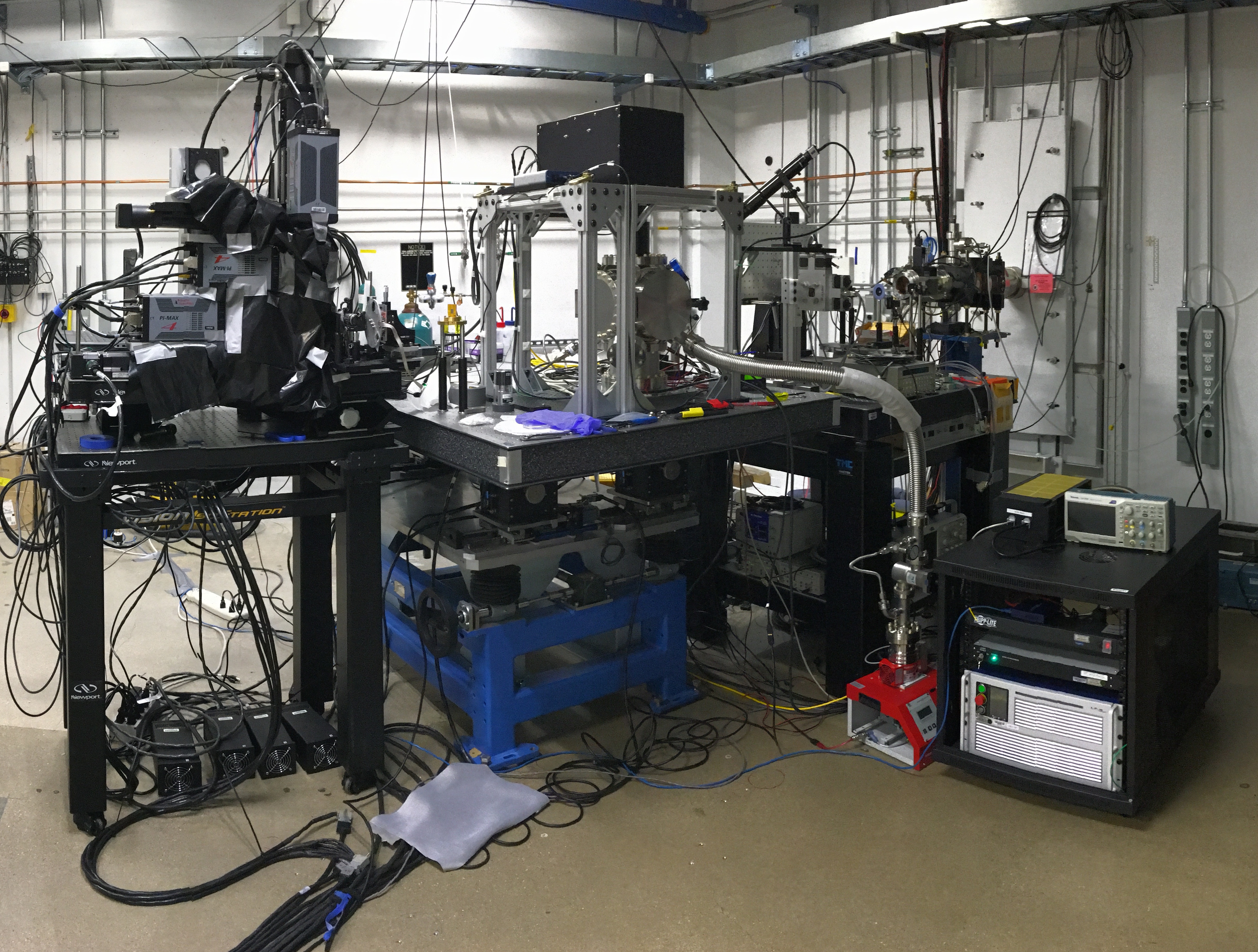

So the researchers constructed a 3D metal printing system linked to a synchrotron X-ray source to enable ultra-high-speed transmission X-ray imaging of the metal melting and fusing process.

“Scanning the laser across the metal surface of the testbed system enables the capture of X-ray images at rates greater than or equal to 100 000 times per second,” says Martin. “On these times scales, we are able to observe the laser-material AM process in slow motion, providing an understanding of how the metal responds to the intense laser heating. The combination of imaging speed and spatial resolution afforded by our setup is unrivalled.”

The complex process of laser heating, including fluid flow in the molten metal and evaporation at the liquid-vapor interface, is difficult to investigate any other way. X-ray imaging, however, reveals instabilities in the molten metal, including surface waves and vapor depressions, which oscillate and collapse during processing.

“Compared to other diagnostic techniques, X-ray imaging is able to capture what is happening under the surface of the 3D printed metal,” points out principle investigator on the project, Jonathan Lee.

The researchers compared the images with computer simulations to validate – and further develop – models of laser-metal interactions. By varying the conditions during the AM process and comparing with simulations, the researchers can determine which factors lead to the formation of undesirable defects such as voids and how they develop.

“This information is critical for identifying how to optimally fabricate metals using 3D printing,” says Martin. “X-ray imaging studies aid in revealing the fundamental mechanisms of metal 3D printing, understanding defect formation in printed parts, and identifying mitigating strategies to eliminate them.”

Although ultrafast X-ray imaging requires a synchrotron X-ray source, the approach can rapidly prototype new materials and the team is expanding its scope to X-ray scattering to look at material cooling and nucleation processes.