3D printing company Additive Industries and its partner Apworks say that they plan to focus on certification and series production in the additive manufacturing (AM) process.

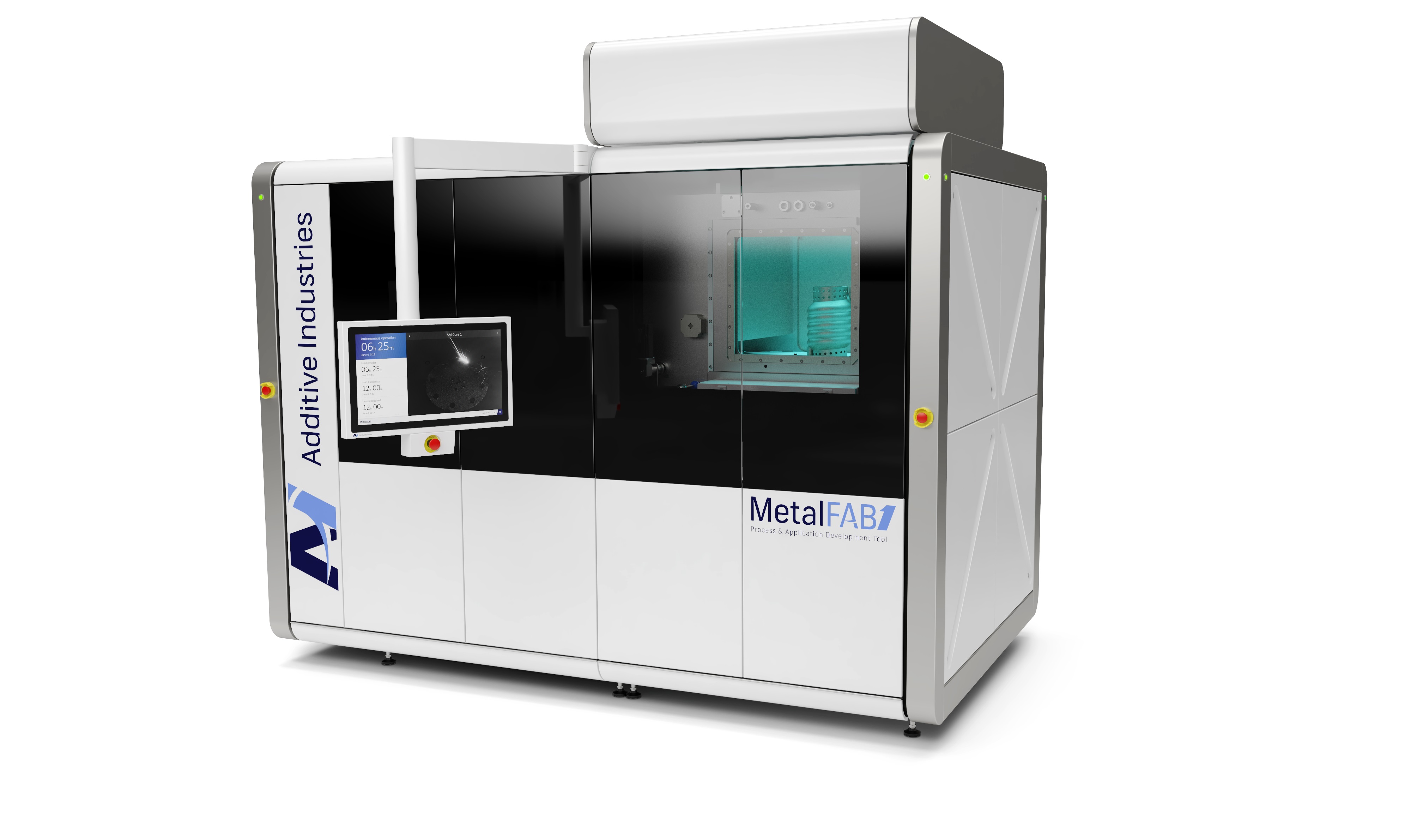

Apworks, a 100% subsidiary of Premium AEROTEC and part of Airbus, focuses on metal AM in non-regulated industries such as automotive, robotics or tooling, as well as new material and software development. According to the companies, they will focus on series production of applications for the aerospace industry using Additive Industries’ MetalFAB1 3D printer.

‘We believe metal additive manufacturing will continue to evolve into a mature fabrication technology and prove to be able to compete with conventional processes like casting, machining and powder metallurgy,’ said Apworks’ CEO, Joachim Zettler. ‘In the next years we expect this market to continuously and rapidly grow and especially in the aerospace industry, new airplanes and aero-engines will contain a substantial number of parts that are additively manufactured.’

This story uses material from Additive Industries, with editorial changes made by Materials Today. The views expressed in this article do not necessarily represent those of Elsevier.