By Kari Williamson

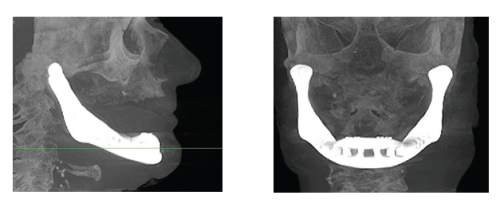

LayerWise printed the titanium metal powder implant design incorporating articulated joints and dedicated features. The reconstruction – postprocessed with dental suprastructure provisions, polished joint surfaces and a bioceramic coating – has been implanted successfully in the patient.

The titanium implant structure was produced layer by layer using LayerWise's metal additive manufacturing technology, where a high-precision laser selectively heats metal powder particles to attach them to previous layers without glue or binder liquid.

Partners: |

|

The patient-specific implant was developed and produced under supervision of Prof. Dr. Jules Poukens, in collaboration with specialised industrial and academic parties in Belgium and The Netherlands, and the titanium metal powder implant was granted the 2012 AM-Award by the Additive Manufacturing Network in Belgium.

Dr. ir. Peter Mercelis, Managing Director of LayerWise, says: “Besides a successful track record in industrial sectors, metal AM is gaining importance in medical implantology. AM’s freedom of shape allows the most complex freeform geometries to be produced as a single part prior to surgery. As illustrated by the lower jaw reconstruction, patient-specific implants can potentially be applied on a much wider scale than transplantation of human bone structures and soft tissues. The use of such implants yield excellent form and function, speeds up surgery and patient recovery, and reduces the risk for medical complications.”