Life depends on keeping things flowing. Blood in our veins, nutrients in our digestive tracts, or air in our lungs, all need to be kept moving. When disease or damage obstruct the flow, medical stents and scaffolds can save lives. They hold crucial arteries open, while these blood vessels repair themselves, or maintain the necessary structure of a damaged esophagus or intestine.

Soon, making stents may be easier than ever, thanks to 3D printing technology. Guillermo Ameer, Cheng Sun and colleagues at Northwestern University in Chicago, US, report their progress with making 3D-printed vascular stents in the journal Materials Today Chemistry.

Despite their benefits and widespread use, existing stents can promote damaging inflammation, may become the site of further blockage due to sluggish flow, or can break in situ. Each clinical condition and each patient also ideally requires a customized stent or scaffolding graft with a specific size, shape, and strength.

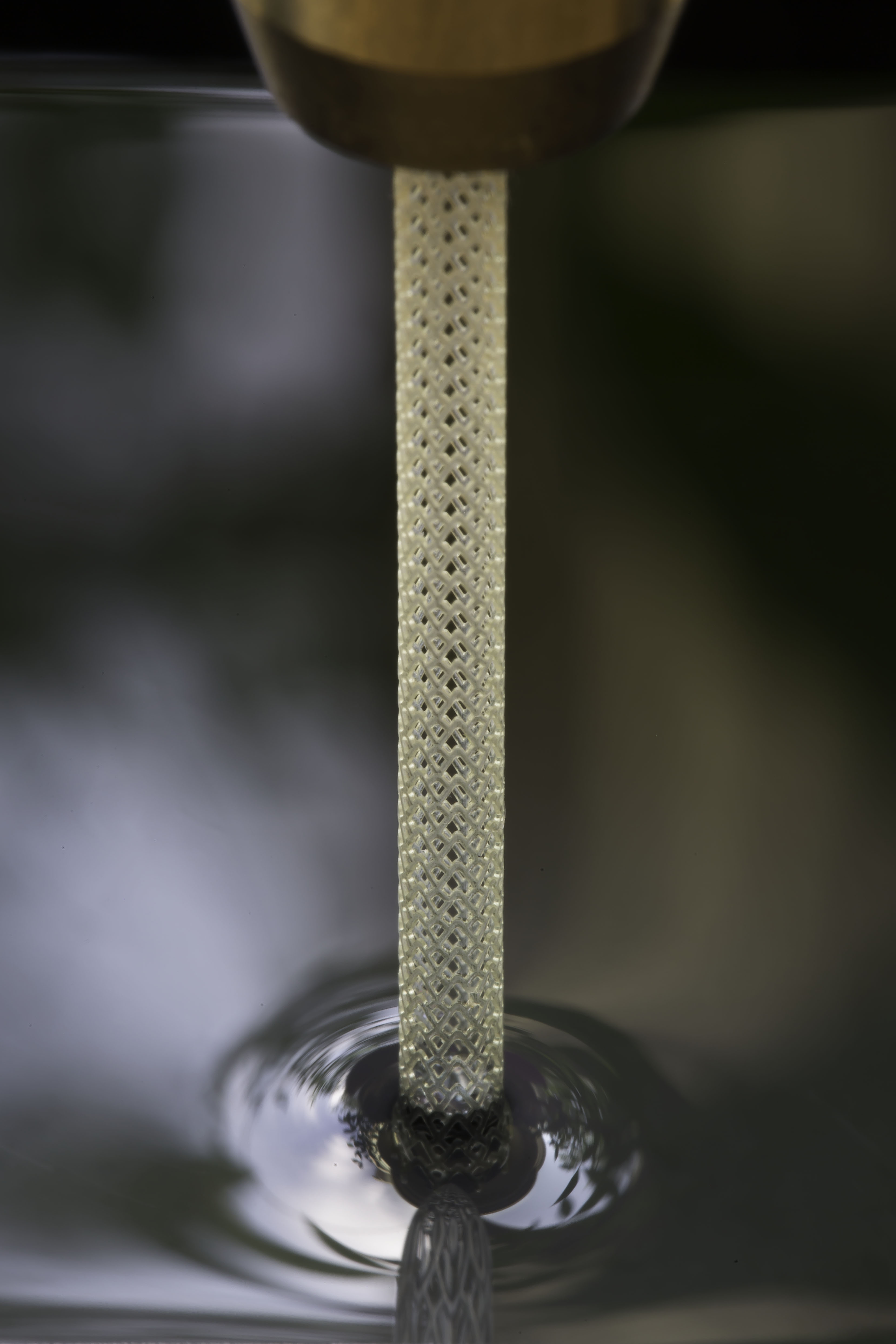

"The need for improved manufacturing techniques and materials to create personalized medical devices to improve the outcome of medical procedures," was the stimulus leading to the development of the new technique, Ameer explains. The researchers explored recent developments in 3D printing techniques, allowing a liquid citric acid-based polymer to be printed into a versatile range of solid and biodegradable 3D structures. They overcame some initial difficulties by designing a new printer. They call their technique Micro-Continuous Liquid Interface Production (microCLIP).

"We were very surprised by how well the microCLIP concept was able to rapidly produce a device with excellent properties," says Ameer. "By marrying the new materials and the high-resolution 3D printing process, it is possible to tailor the stent to address an individual patient’s needs, all at high fabrication speed and precision," adds Sun. The procedure created very thin but strong scaffolding structures that should minimize the disturbances to blood flow and be able to fit inside very small blood vessels. The stent struts can now be made as thin as a human hair.

The work to date has created stents that perform well in tests designed to simulate the chemical and mechanical conditions of their likely operating environment. These trials include examining the interaction of the material with cultured cells.

The next stage will be to test the materials in live animals and then move on toward clinical trials. "We hope to work closely with industry to bring our materials to the market," says Ameer.

-- Ameer, G., Sun, C. et al.: High-speed on-demand 3D printed bioresorbable vascular scaffolds. Materials Today Chemistry (2017)