A team from the DoE’s Oak Ridge National Laboratory in the US has demonstrated a way to flexibly fabricate 3D printed permanent magnets in complex shapes that improve upon traditional approaches in terms of material conservation and cost. The magnets, produced by additive manufacturing, outperform bonded magnets, as well as conserving the rare materials used in the strongest magnets. Printing strong magnets in this way could lead to more efficient electric motors and generators.

The team, whose work was reported in Scientific Reports [Li et al. Sci. Rep. (2016) DOI: 10.1038/srep36212], fabricated isotropic, near-net-shape, neodymium–iron–boron (NdFeB) bonded magnets using a large printer called a Big Area Additive Manufacturing (BAAM). NdFeB magnets are the most powerful available, and are already incorporated into everyday products such as computer hard drives and headphones, as well as the environmentally friendly energy technologies of electric vehicles and wind turbines.

Standard sintered magnet production can lead to material waste of as high as 50%, a significant problem for rare earth elements such as neodymium and dysprosium used in permanent magnets, so replacing the critical elements with non-critical ones is important for conserving these elements. The additive fabrication approach used in this study captures and then reuses the materials with nearly zero waste, and the 3D magnets produced show the same or even better magnetic, mechanical and microstructural properties than bonded magnets fabricated from traditional injection molding with the same composition.

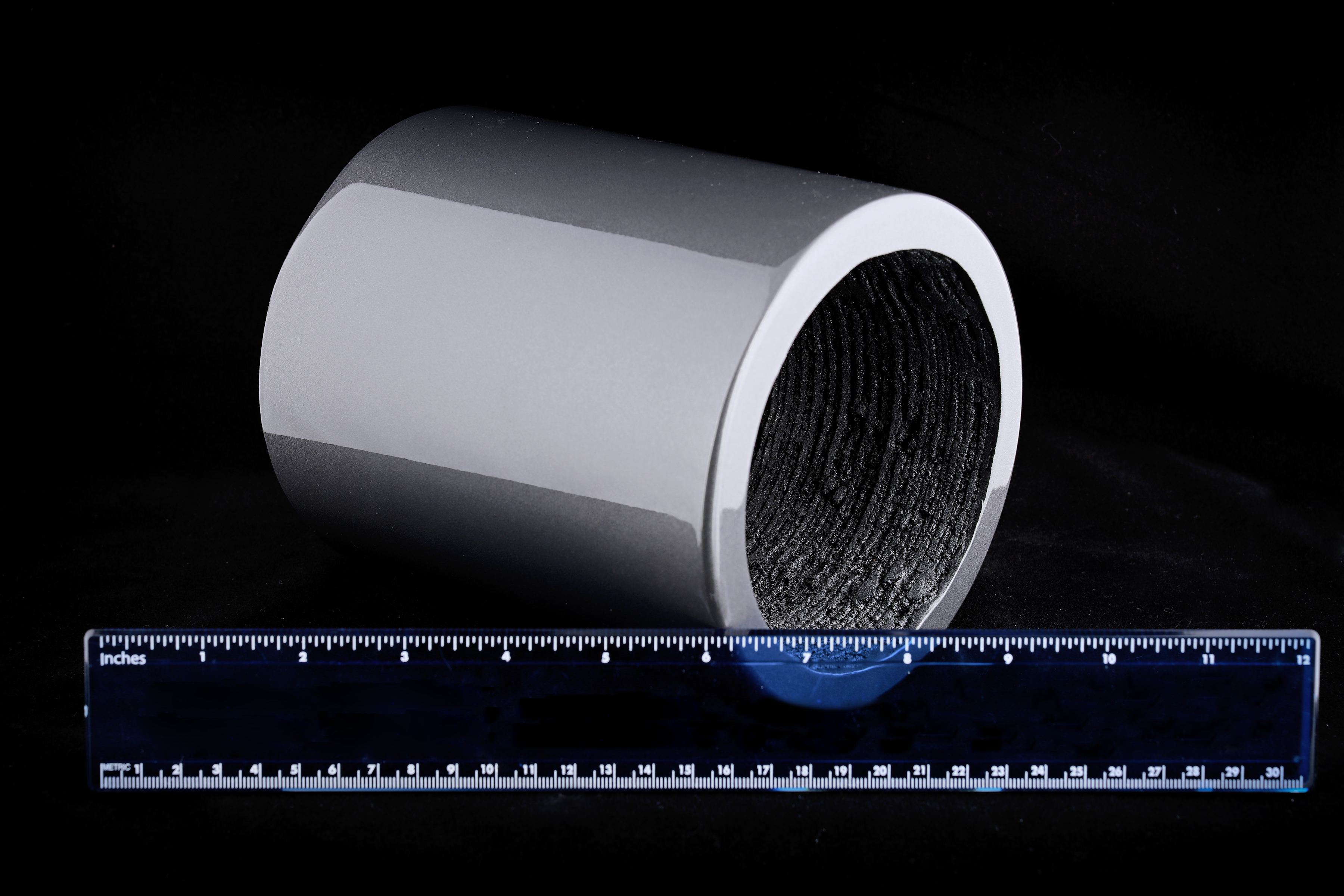

To initiate the additive manufacturing process, the team used composite pellets made of 65 volume percent isotropic NdFeB powder and 35% polyamide, which were melted, compounded and extruded on a layer-by-layer basis by BAAM into specific forms. The approach allows for a range of shapes that can be made easily and quickly using computer-assisted design, obviating the need for creating new molds and tooling for each form, as is the case for traditional injection molding. Principal investigator M. Parans Paranthama said “We have printed a complex shape, with near zero waste, magnetic and mechanical properties better than the traditional injection molded NdFeB using the same volume percent of magnet in nylon polymer composites”.

The researchers are now investigating the printing of directional bonded magnets, which are stronger than isotropic magnets that have no preferred magnetization direction, as well as the effect of binder type, the loading fraction of magnetic powder and processing temperature on the magnetic and mechanical properties of printed magnets. As co-author John Ormerod points out, “This work has demonstrated the potential of additive manufacturing to be applied to the fabrication of a wide range of magnetic materials and assemblies”.