NASA engineers have 3D printed the first full-scale, copper rocket engine part as part of the space agency's bid to develop technology for Mars exploration.

‘Building the first full-scale, copper rocket part with additive manufacturing is a milestone for aerospace 3D printing,’ said Steve Jurczyk, associate administrator for the Space Technology Mission Directorate at NASA Headquarters in Washington. ‘Additive manufacturing is one of many technologies we are embracing to help us continue our journey to Mars and even sustain explorers living on the Red Planet.’

Numerous complex parts made of many different materials are assembled to make engines that provide the thrust that powers rockets. Additive manufacturing (AM) could reduce the time and cost of making rocket parts such as the copper liner found in rocket combustion chambers where super-cold propellants are mixed and heated to the extreme temperatures needed to send rockets to space.

Inside the combustion chamber, propellant burns at more than 5,000°F. To prevent melting, hydrogen at temperatures less than 100 degrees above absolute zero circulates in the cooling inlets visible along the top rim of the chamber.

‘To circulate the gas, the combustion chamber liner has more than 200 intricate channels built between the inner and outer liner wall,’ said Chris Singer, director of the Engineering Directorate at NASA’s Marshall Space Flight Center in Huntsville, Alabama, where the copper rocket engine liner was manufactured. ‘Making these tiny passages with complex internal geometries challenged our additive manufacturing team.’

Materials characterization

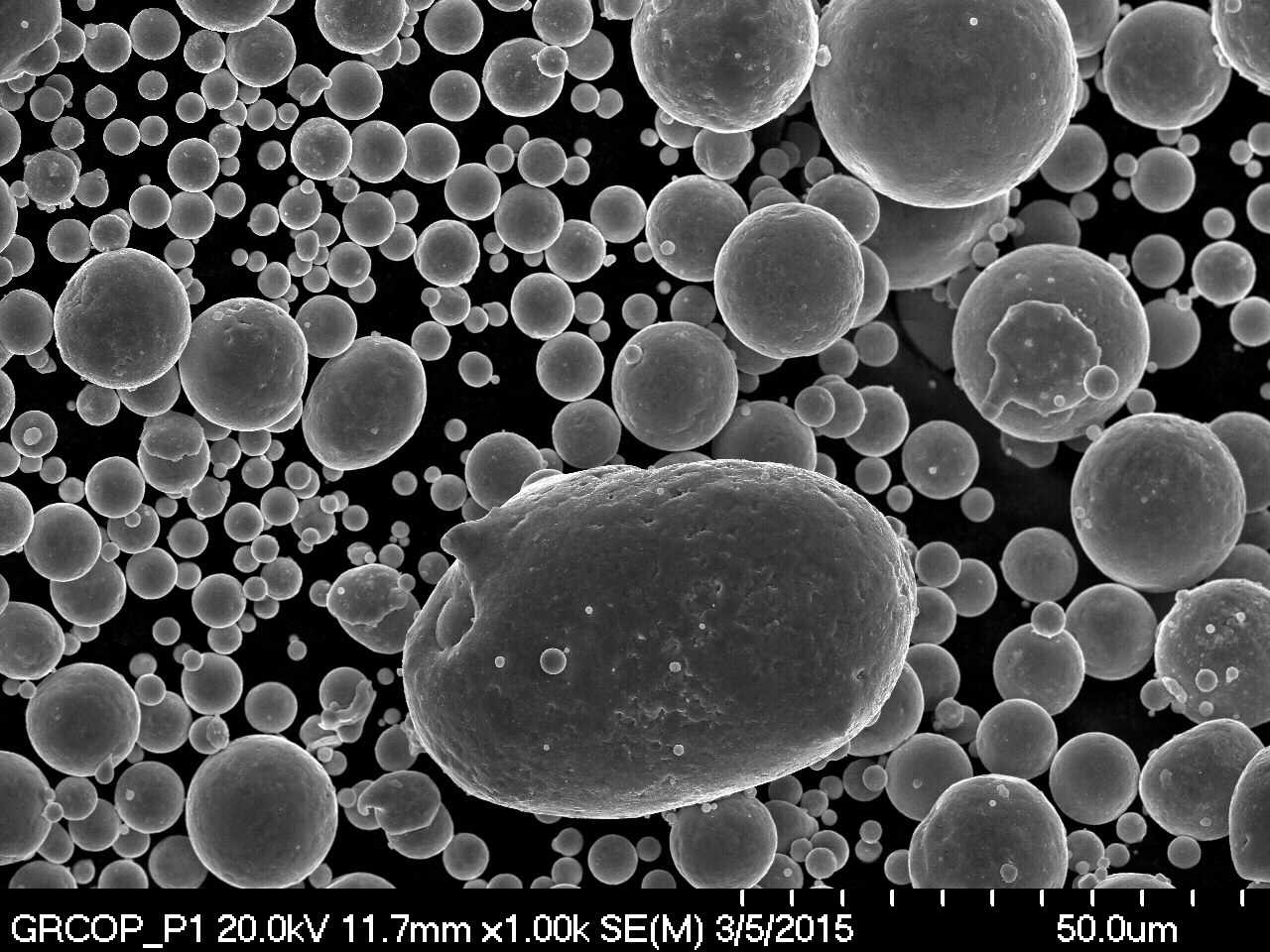

The part is built with GRCo-84, a copper alloy created by materials scientists at NASA’s Glenn Research Center in Cleveland, Ohio, where materials characterization helped validate the 3D printing processing parameters and ensure build quality. The aim is to develop an extensive database of mechanical properties that will be used to guide future 3D printed rocket engine designs.

‘Copper is extremely good at conducting heat,’ said Zach Jones, the materials engineer who led the manufacturing at Marshall. ‘That’s why copper is an ideal material for lining an engine combustion chamber and for other parts as well, but this property makes the additive manufacturing of copper challenging because the laser has difficulty continuously melting the copper powder.’

A selective laser melting machine in Marshall’s materials and processing laboratory fused 8,255 layers of the copper powder to make the chamber in 10 days and 18 hours. Before making the liner, materials engineers built several other test parts, characterized the material and created a process for additive manufacturing with copper.

‘Our goal is to build rocket engine parts up to 10 times faster and reduce cost by more than 50%,’ said Chris Protz, the Marshall propulsion engineer leading the project. ‘We are not trying to just make and test one part. We are developing a repeatable process that industry can adopt to manufacture engine parts with advanced designs. The ultimate goal is to make building rocket engines more affordable for everyone.’

Extreme temperatures

The next step in this project is for Marshall engineers to ship the copper liner to NASA’s Langley Research Center in Hampton, Virginia, where an electron beam freedom fabrication facility will direct deposit a nickel super-alloy structural jacket onto the outside of the copper liner. Later this summer, the engine component will be hot-fire tested at Marshall to determine how the engine performs under extreme temperatures and pressures simulating the conditions inside the engine as it burns propellant during a rocket flight.

This story is reprinted from material from NASA, with editorial changes made by Materials Today. The views expressed in this article do not necessarily represent those of Elsevier.