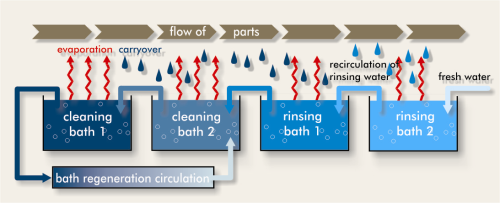

Industrial and aqueous cleaning processes of metal parts consist of cleaning and rinsing procedures in several baths (see Fig. 1). First, the cleaning baths remove the contamination of the metal surface, followed by the rinsing baths for eliminating further contamination as well as cleaning agent residues. The cleaning baths have a temperature of 40–80°C (104–176°F). The resulting evaporation of water is compensated by a recirculation of rinsing water. A regeneration circulation ensures stable bath condition due to a continuous removal of bath contamination.

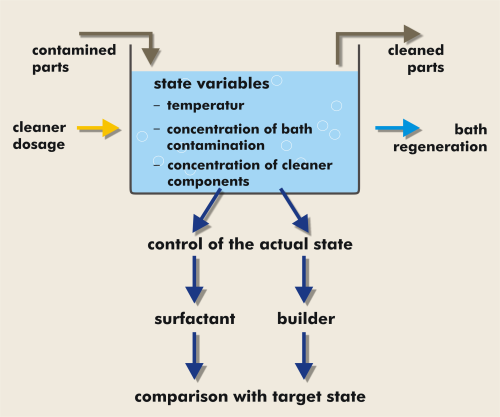

Aqueous cleaning processes require optimal and stable conditions of the parameters that influence cleaning results in order to ensure a high process reliability (see Fig. 2). These parameters entail:

- concentration of cleaning agent components (builder and surfactant)

- bath contamination

- bath temperature

- agitation

The main goal of process management is to continuously monitor the condition of the cleaning bath and control the condition in a way that ensures sufficient cleaning quality can be achieved by using minimum amounts of water, cleaning agent, and energy.

Here the main focus is on maintaining the concentrations of the cleaning agent components (surfactant and builder), which are defined as optimal by the manager of the cleaning processes. The degree of consumption for both cleaning agent components, surfactant, and builder, is different and an adequate dosage for each component is required.1 The concentration of the cleaning agent components change constantly due to various reasons. For example, carry-over effects by the flow of parts, removal of cleaner components because of bath regeneration (e.g., ultra-filtration), or diluting processes over the cascade.

An optimal match of all influencing parameters is the basis for economical and ecological process management. The required cleaning quality is only guaranteed if the process, the plant, and the cleaning chemicals are adapted to the part being cleaned and its contamination. This happens with the cooperation of the person in charge of the cleaning process working in concert with the cleaning agent manufacturer and plant manufacturer, before putting a new plant into operation or prior to changing plants or processes. Desired process parameters, as well as the cleaning agent concentration and its acceptable limit values, are determined on the basis of individual experiences, test runs, or optimization runs in a laboratory and/or production plants in order to reach the required cleaning quality. Currently, many cleaning agent components get strongly overdosed in order to ensure the cleaning power in baths.

An analysis of the process management of cleaning metal parts was carried out by the Institute of Electromechanical and Electronic Design of the Dresden University of Technology to help understand the current processes employed and the state of technology in the industry. Therefore, managers of cleaning processes were asked about the specific cleaning task of parts and the corresponding process management. Here, the focus was on the European automobile industry and its categories: car body; powertrain and their elements; hydraulic parts; and bearings.

The following information could be deduced from conversations with 73 professionals from different companies:

- Although cleaning quality is tested regularly by the majority (74%), it is mostly evaluated only with subjective methods such as visual inspection or by checking the quality of the subsequent process

- Only 23% of those questioned inspect the cleaned surface through a measurement

- The cleaning agent manufacturer cooperates with the plant operator in 51% of the cases regarding desired parameters of the cleaning agent concentration. In 14% of the cases, the cleaning agent manufacturer determines this value on its own. Consequently, it can be said that the determination of the target state of a cleaning bath is predominantly based on the experience of the chemicals manufacturer.

- In 84% of the cases, the plant operator controls the cleaning agent concentration. He is, therefore, responsible for the optimization of the current process

- 78% of those asked monitor the builder concentration, whereas 79% of them monitor using titration

- Only 49% monitor the surfactant concentration, and 51% of them use the surface tension measurement for this value

- 33% of the respondents have an automatic dosing system for the cleaner. Only 56% consider their dosing optimal.

- 38% of those questioned think about further optimization possibilities in the process management through bath monitoring and bath regeneration actions

The analysis shows that the cleaning process of metal parts has not been fully mastered in comparison to other production processes (e.g., mechanical processing). This especially applies to a continuous control of input and output parameters, as well as the process parameters, in order to ensure stable part quality. The level of development of the process management for parts cleaning is in conflict with the process reliability requirements because 83% of the people interviewed state, in detail, consequential damages due to process instabilities. This fact indicates that 83% of the professionals polled knew about the consequences of a deficient cleaning process.

There is an optimization potential regarding economical and ecological points of view. Regulation of the essential process parameters for cleaning quality (i.e., the cleaning agent concentration and a consumption-oriented dosing) only occurs in single cases. The reasons for these problems are evident in the high volume of different yet interrelated parameters in the cleaning process and a missing systematic preparation and generalization of several individual experiences in order to realize high process reliability. These problems can be solved by monitoring the process conditions with the help of simple process parameters. Therefore, it is required to have a practicable measuring technology that can be used for the analysis as well as for continuous or discrete monitoring of the processes.

The surfactant concentration’s influence on cleaning power is measured with the help of the dynamic surface tension. For monitoring and dosing the builders it is possible to control their concentration by measuring the conductivity or by using acid–base titration. A continuous monitoring of the cleaning agent concentration allows a consumption-oriented dosing and, thus, an economic and ecological optimization of the cleaning processes. Optimization contains:

- a decrease in costs of using cleaning agents

- avoiding accumulation of cleaning agent components in subsequent rinsing baths

- an extension of bath life

- a decrease in costs of water and wastewater management

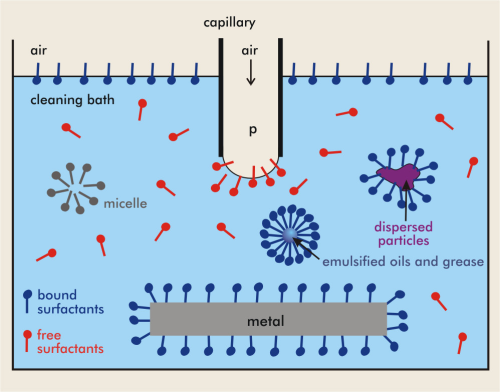

Monitoring the surfactant concentration and dosing according to consumption are possible due to the parameter surface tension. Therefore, bubble pressure tensiometers are used to measure the concentration of free surface active agents, as shown in Figure 3. Free surfactants that are not bound to oil, contamination, and the metal surface attach to the developed bubble at the capillary peak. In cleaning processes, only these free surfactants are available to remove contamination and oil from the metal surface. The current cleaning power can be controlled using this method.

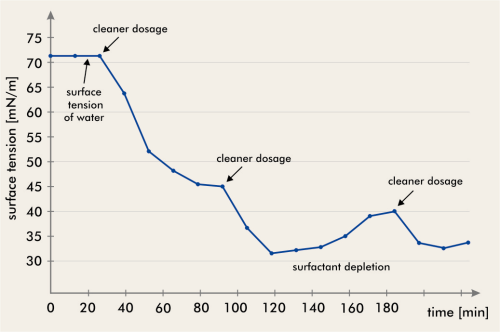

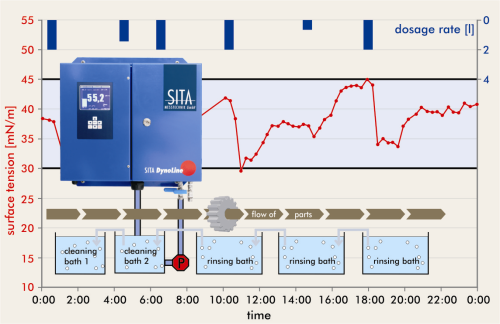

Monitoring the surfactant concentration by measuring the surface tension of process liquids in cleaning baths allows a proper use of the surfactant components (wetting agent). Required extra dosages can be recognized using the resulting measurements. In order to visualize the monitoring procedure, Figure 4 shows the result of continuous measurement in a cleaning bath. At the beginning of the preparation the surface tension value of water can be seen first (72.8 mN/m at a bath temperature of 20°C). When adding surfactants, the surface tension decreases.

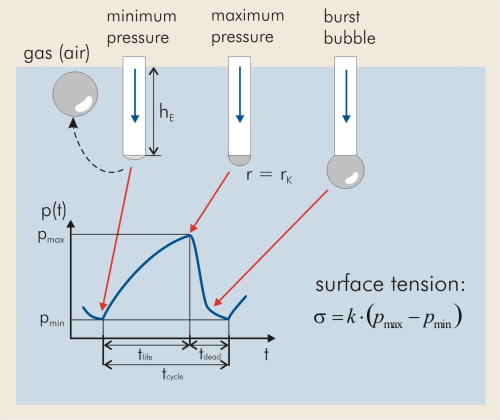

Bubble pressure tensiometers measure the surface tension on the basis of the differential pressure method. In this process, air is pumped through a capillary in the liquid to be analyzed (Fig. 5). A special sensor measures the internal pressure of the developed bubble on the capillary peak. The dynamic surface tension is calculated by making up the difference of the maximum and minimum bubble pressure and the usage of the calibration factor k:

s = k • Dp, with Dp = pmax – pmin

The bubble pressure tensiometers are calibrated in pure water, free of surfactants. The calibration factor k is determined automatically by the measuring device independent of the bubble lifetime. The differential pressure method considerably simplifies the operation with the tensiometers because the measurement does not depend on the depth of immersion of the capillary into the liquid.2

In contrast to static methods of measuring surface tension, the dynamic measuring method allows measurement of the surfactant concentration above the critical micelle concentration (CMC), which is the standard concentration range used in water-based cleaning processes. The precondition for the measurement is the quantification of the relation between the process value surfactant concentration and the surface tension.

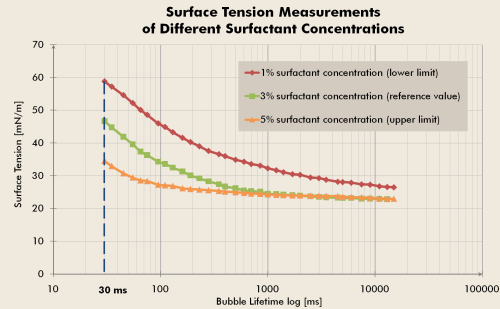

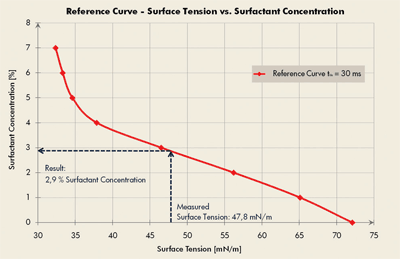

The dynamic surface tension depends on the age of a newly created surface. The quantitative differences of dynamic surface tension values of different surfactant concentrations depend on the surface age (bubble lifetime, see Fig. 5). The one-time determination of the optimal bubble lifetime can be processed in a laboratory by the following procedure. The AUTO-mode of the tensiometer is used to measure the surface tension of particular reference samples with a known concentration over the complete bubble lifetime range. The optimal bubble lifetime value can be found at the highest difference of the surface tension measurement values (see Fig. 6). Afterward, a reference curve based on different reference samples with known surfactant concentrations can be developed. The surfactant concentration of a measured surface tension in the process can be determined using the reference curve.

For economical process management and high process reliability, the surfactant concentration has to be kept within the given limits.

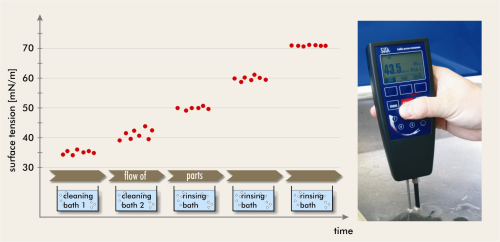

According to specific process conditions, hand-held tensiometers for a periodical measurement or process measuring technique for continuous monitoring can be used for analysis, as well as monitoring the process parameter surface tension.

In order to realize efficient measurements during the process or in the laboratory, measuring instruments have to be reliable, quick, and easy to operate. The realization of those characteristics were essential for the development of a new hand-held tensiometer, the SITA DynoTester. The surface tension and the temperature of the cleaning solutions are measured by pushing one single button. Parameters as bubble lifetime or average determination are predefined and can only be changed in the administrator mode. These characteristics minimize the risk of operating errors.

The measuring results can be saved in 25 storage spaces in the device for later evaluation. The integrated power supply allows a mobile use of up to 10 hours and ensures high flexibility. The adjustable average determination increases the reliability measurement results in non-homogeneous liquids—for example, in emulsions. One measurement can be carried out within 10 seconds depending on the chosen bubble lifetime. Therefore, the SITA DynoTester is a new, economical alternative for the measurement of process parameter surface tension.

Figure 7 shows the results of periodical measurement of cleaning baths in a plant. The diagram of the surface tension values shows stable conditions within the process baths and over the bath lifetime. In the last rinsing bath, the surface tension reaches the same value of water, which means that the surfactant concentration decreases to zero.

Continuous bath monitoring requires measuring samples representing the actual condition of the bath that can be assured by using a bypass. Samples for continuous measurement in a bypass have to be homogeneous and must be kept on a defined temperature level as well. A special measuring vessel with slow-flowing characteristics in the capillary area minimizes negative influences on the bubble and avoids particle accumulation. The flow rate of 2 l/min ensures a sufficiently homogeneous and non-demulsifying sample near the bath temperature level.

A crucial problem is the lifetime of the capillary. Accumulations of cleaning bath ingredients can change the capillary characteristics during the time of usage. Common glass capillaries used in the bubble pressure tensiometry were substituted with a PEEK-capillary consisting of a more robust and hydrophobic material. The PEEK material and the increasing diameter behind the new capillary’s tip minimize the capillary effect, which means that the sample hardly gets into the measuring capillary. Under the same conditions, a conventional laboratory capillary has a lifetime of approximately 300 hours in comparison to an optimized PEEK capillary with a lifetime more than 10 times higher. This high insensitivity against accumulations ensures long-lasting and reproducible bubble generation.2

The process measuring technology SITA DynoLine is used for continuous bath monitoring. The fully automatic device works as a plant component and is adapted to the specific requirements of the process, the chemistry, and the plant. It differs from other sensors and conventional surface tension measuring technologies in that the SITA DynoLine automatically controls the supply of the sample, the calibration water, and the self-cleaning procedure. Other essential characteristics include a self-monitoring function, error detection, and alarm signaling for trouble-free operation. Any changes in the capillary characteristics that occur (e.g., through an accumulation of contamination) can be identified by the measuring instrument itself due to the regular self-monitoring function.

For controlling the liquids, the instrument has a valve for both the sample and the water. Furthermore, it has a pressure sensor for monitoring the input pressure. Together with calibration water, the sample is led back into the bath without pressure (in general, the evaporation of bath liquid is higher than the supply of calibration water). All measuring values can be saved in the instrument for one year in order to record the measurements. Interfaces allow communication with the superior control system of the cleaning plant. The upgrading of a plant for automatic dosing can be easily achieved in order to keep the surfactant concentration of a process within an optimal range (see Fig. 8).

In many applications of surface treatment processes, from car bodies to precision parts for pumps and bearings, the cleaning processes were successfully optimized by monitoring and dosing the cleaning agent components (surfactant and builder automatically). Furthermore, control of the process achieves sufficient cleanliness quality with a minimum use of water, cleaning agent, and energy. Finally, a new dimension in the process reliability as well as in the economic and ecological process management may be achieved.

Notes

- Brunn, K. Besser und weiter. Metalloberfläche (2003) H.11, S15–16.

- Haberland, R. Dimensionierung und Gestaltung von Oberflächenspannungsmessgeräten für den Prozess-Einsatz. Dissertation, Technische Universität Dresden, 2004.

Bio

Daniel Schümann is the application manager for SITA Messtechnik GmbH, a Dresden, Germany-based company that develops and sells user-friendly instruments for measuring the dynamic surface tension of liquids, measuring solutions for process control and monitoring on the basis of surface tension measurements, as well as cleanliness inspections instruments using the fluorescence method. Schümann is also working on his doctorate in the field of process measuring and control technology for industrial cleaning processes.