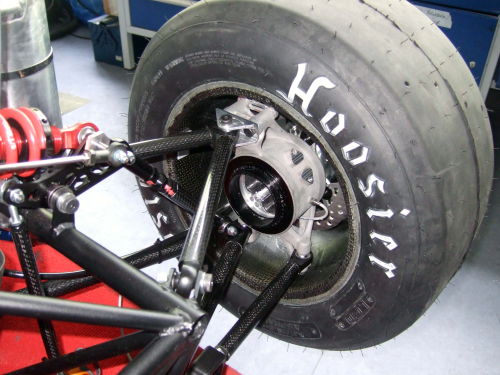

A key part of a car’s front axle is the steering knuckle – a stub axle that connects the tie rod, suspension, brake and wheel. It transmits all the forces from the wheel to the vehicle chassis, so it has to be strong. In the case of a race car, it also needs to be light.

This is true of all race car components, but for the knuckle it is especially important, as it forms part of the unsprung mass of the vehicle. Less weight below the suspension improves shock absorption, thereby enhancing handling and bringing down lap times.

Designers are, therefore, faced with the tricky task of finding the optimal balance between rigidity and weight. Moreover, this and other parts often need to be produced quickly. The young constructors of Rennteam Uni Stuttgart found a solution: growing the knuckle layer by layer using additive manufacturing, or 3D printing. The team is an independent club that takes part in the Formula Student racing series across Europe and also participates in other international competitions.

Previous production technologies offered the Stuttgart race team too little room to maneuver in the search for the perfect weight-strength balance, as team member Yannick Löw explained: “The wheel mount we had been using over the last few years was a good compromise, but we were sure we could improve on it. We previously produced the part using an aluminium precision casting process, which led to limitations in freedom of design, notably that the part had to be solid throughout.”

Investigation into new, innovative ways of manufacturing the steering stub axle led the students towards additive manufacture and EOS, which agreed to support Rennteam Uni Stuttgart. As early as the conceptual design phase for their Formula Student 2012 competition car, the engineers used CAD software from EOS partner, London firm Within Technologies Ltd, a young company whose programmers have written software specifically for the additive manufacturing process. The program allows 3D printing of optimised structures of variable density, following examples found in nature. In this case, Rennteam Uni Stuttgart constructors were able to match the steering knuckle’s structure accurately to the required physical properties, leaving it solid where strength was needed and introducing hollow parts where expedient to lower the weight. The part was manufactured using aluminium AlSi10Mg powder at EOS’ headquarters in Krailling, near Munich.

The fact that the development and production time was significantly shorter compared to the previous production process was important for the team. With direct metal laser sintering, or DMLS, there is no need to make a mould to cast the part. In addition, the entire process from design through to fabrication of the finished, fully functional component is more precise, so less reworking and refining is required. In this case, the constructors reached a high level of production quality in a short time, so the part was almost immediately race-ready.

The advantages can be summed up in figures released by the team. The weight of the knuckle was reduced by 660 grams, a saving of 35% compared with the previous cast part. At the same time, the engineers succeeded in increasing its rigidity by 20%. According to Rennteam, these are big numbers in motorsport and translate into faster lap times and reduced fuel consumption.

Fast forward… Rennteam Uni Stuttgart won the final race of the Formula Student series last year at the Hockenheimring and were crowned Formula Student Germany Champions 2012. “We were thrilled to bring the Formula Student Germany title to Stuttgart,” said Yannick Löw. “The freedom in the manufacturing process offered by DMLS technology from EOS played an important role in our success.”